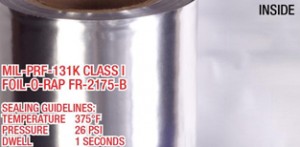

FR2175

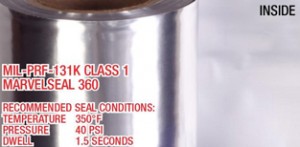

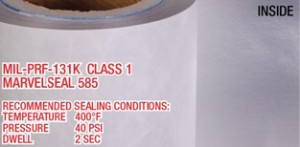

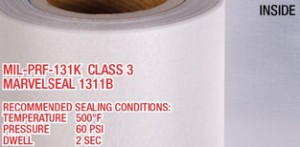

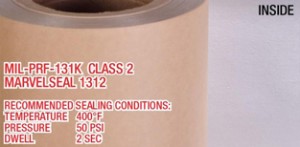

MIL PRF 131 CLASS 1 – FFP

MILITARY SPECIFICATION

MILITARY SPECIFICATION

FILM: MIL PRF 131 C1 – FFP

POUCH: MIL DTL 117 T1 CE S1

Exterior: Foil

Recommended Sealing Conditions:

Temperature 375 °F | Pressure 26 PSI | Dwell 1 SEC

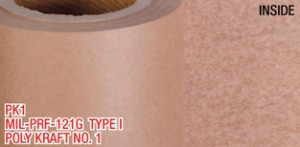

Barrier Material: Water vapor proof, Greaseproof, Flexible, Heat-Sealable, Class 1

Application:

FR-2175B is a foil barrier material used where very low oxygen and moisture levels are required. It is silver in color with red Mil Spec printing. It is used extensively in military applications where a cost-effective, strong, high barrier material is required. This FDA approved material is also available without the Mil Spec and is therefore unprinted (FFP500).

Converting:

It can be converted in many ways: 2-seal pouch, 3-seal pouch, side gusset, stand up pouch and tubing. Features include: recloseable zipper, tear notch, round hang hole, and sombrero hang hole. The FFP500 can also be surface printed or reverse-trapped printed. It is available in web widths to 60”

Physical Properties:

| PROPERTIES | TEST METHOD | UNIT OF MEASURE | TYPICAL VALUE |

| Caliper | mils | 5.0 | |

| Yield | sq.in/lb | 5400 | |

| MVTR | Mocon | gms/100² in./24 hrs | .0006 |

| OTR | Mocon | CC/100² in./24 hrs | .0006 |

| Tensile MD | ASTM D882 | Lbs. at break | 34 |

| Tensile XMD | ASTM D882 | LBS. at break | 29 |

| Tear MD | ASTM 689 | Grams | 64 |

| Team XMD | ASTM D689 | Grams | 64 |

| Alum. Pinholes | Pinholes/ft² | 100 |

The values indicated in this document are the results of tests made in compliance with the normal standards. They are given as an indication and should be considered as average values and given without any obligation on our part. This data was provided directly to Shannon from our film supplier.

MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION MILITARY SPECIFICATION

MILITARY SPECIFICATION